Well I don’t know if it is the age-old question or not, but it is one that has been discussed in the dental lab industry for the last several years, 4-axis or 5-axis. I’ve had a lot of people tell me “why would you have a dental lab limit themselves to a 4-axis mill?” It isn’t really a matter of limiting yourself, but taking a look at your business and making an educated decision on the mill that best fits your dental lab’s needs.

Well I don’t know if it is the age-old question or not, but it is one that has been discussed in the dental lab industry for the last several years, 4-axis or 5-axis. I’ve had a lot of people tell me “why would you have a dental lab limit themselves to a 4-axis mill?” It isn’t really a matter of limiting yourself, but taking a look at your business and making an educated decision on the mill that best fits your dental lab’s needs.

The Difference

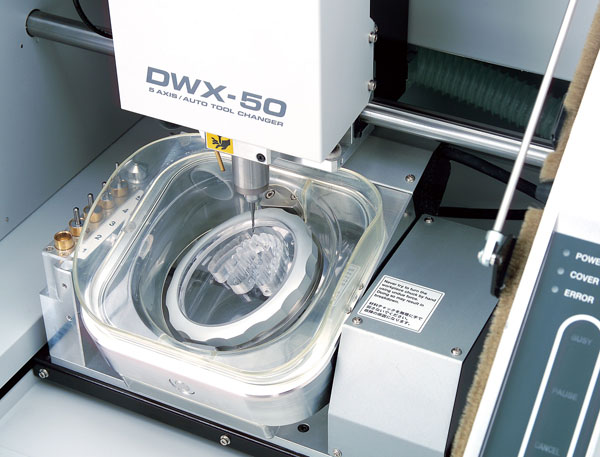

As a refresher, or for those of you just looking into dry milling, the biggest difference between a 5-axis mill and a 4-axis mill is the ability to do undercuts. If you are going to mill custom implant abutments, bars or partial frames then a 5-axis mill is necessary. Other differences include the amount of material used, tool life and milling time. Because of the nature of 4-axis milling, there are times when you would need a thicker disc to mill a unit on a 4-axis machine versus a 5-axis machine. This is because a 5-axis mill can eliminate more undercuts with machine positioning, where as a 4-axis mill might need to angle a unit more in the stock material.

The Misconception

There seems to be a misconception that there is a difference when it comes to the anatomy of say a crown milled on a 4-axis mill versus a 5-axis mill. When it comes to anatomy there really is very little difference between a 4 and 5-axis mill. You can mill the exact same full contour crown on our 4-axis machine and our 5-axis machine and you are not able to tell the difference between the two. The milling strategies play the biggest factor in anatomy, so you are able to mill a very nice looking crown on a 4-axis mill.

Making the Decision

Most restorations that are milled in a lab such as crowns, bridges, copings, onlays and inlays can be milled on a 4-axis machine. Determining where your business is now and where you want it to go in the future should help you decide on what type of mill to purchase or lease. If 85% to 90% of your business is single units and you expect it to remain like this, then a 4-axis mill will suit your needs. If you are a lab that is doing or will be doing more complex cases, such as abutments and bars, then a 5-axis is the mill for you. It all goes back to asking yourself (and your reseller) the right questions to make sure you are making the best decision.