In this post, I’d like to point out key differences and similarities between SUM3D Dental CAM and MillBox. The objective is for existing SUM3D Dental users to evaluate and consider key features for upgrading software. These could also be considerations for individuals that are new to CAD/CAM – many of whom may be purchasing their CAM Software for the first time.

One of SUM3D’s strong points over its competition is the level of automation concerning the CAM workflow and the unprecedented level of dental-specific optimizations that have been made for the CAM over the years. Many features developed and implemented are suggestions that often stem directly from end-user feedback and in working with CAD/CAM leaders spanning the globe.

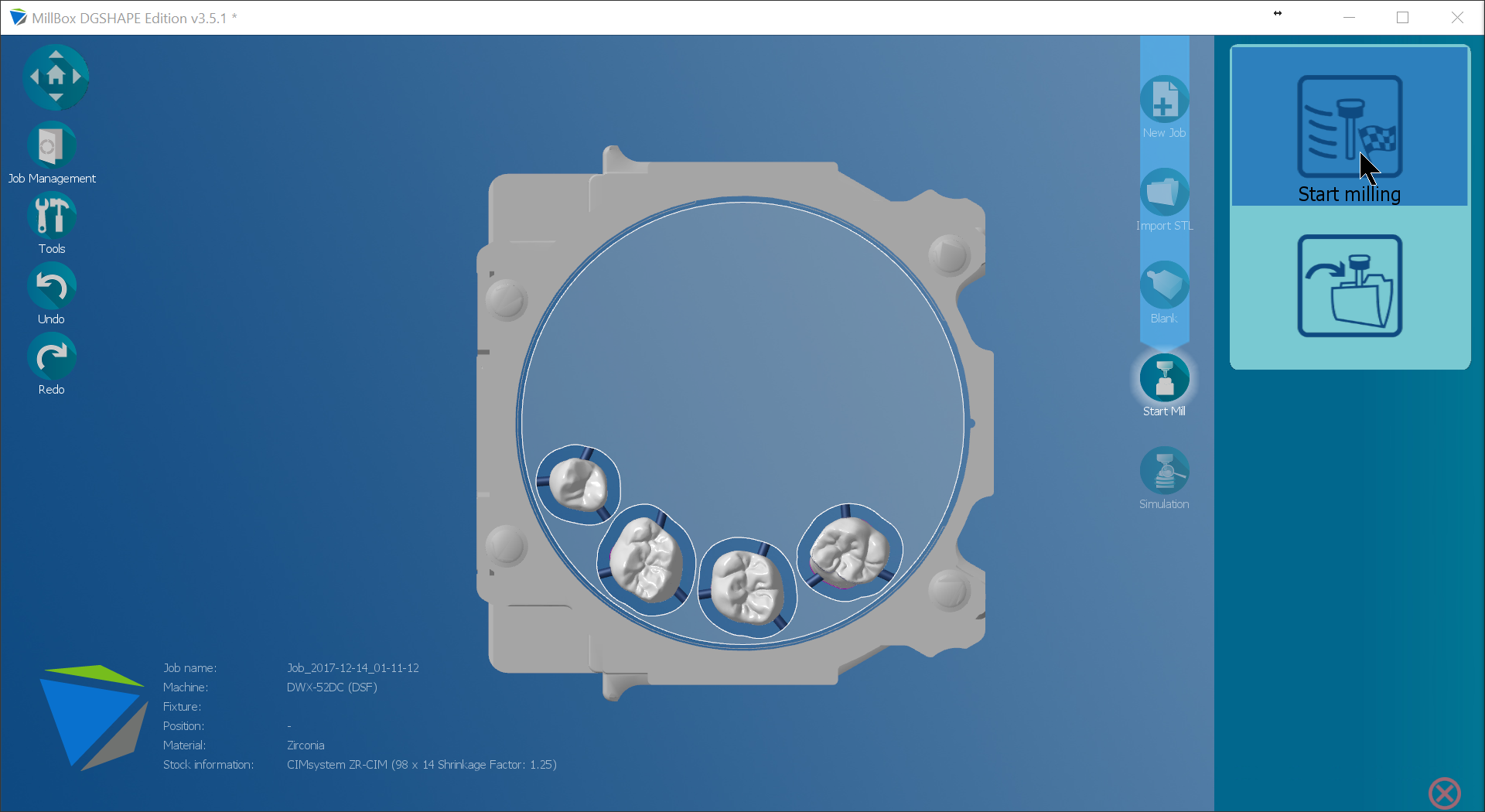

MillBox aims to add onto SUM3D’s success by replacing the older dated interface. This has been accomplished by re-designing the OPEN dental CAM experience from the ground up. MillBox has been custom-tailored to be simple and easy for dental lab and clinical professionals to train and operate.

Here are some features at a glance that show how the MillBox upgrade has improved over the SUM3D Dental CAM workflow:

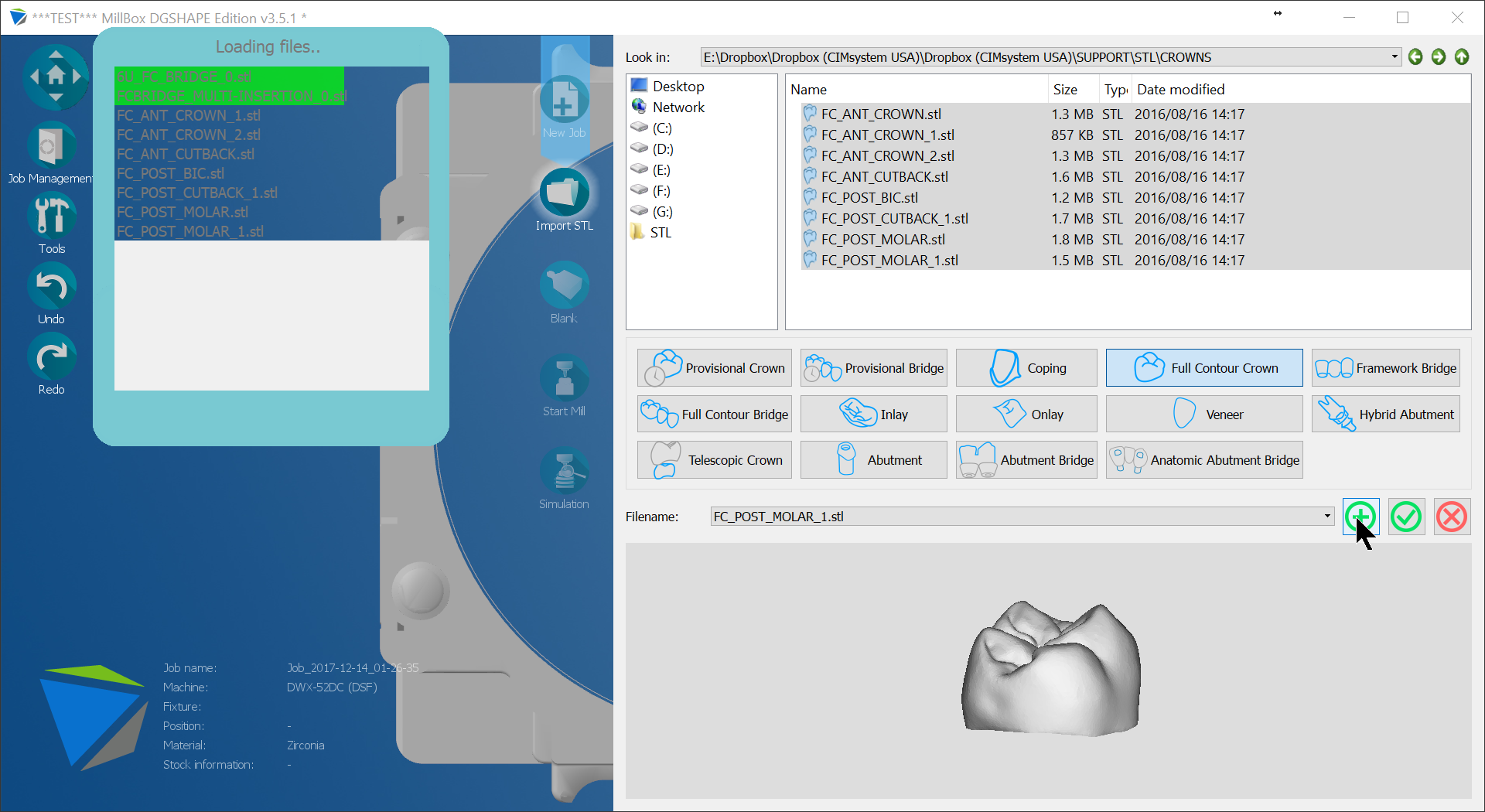

Simple & Intuitive Interface

MillBox has drastically reduced the number of icons displayed. The guided workflow toolbar on the right side indicates current stage of the nesting workflow that the user is in. There are many distractions in production and being able to pick up exactly where you left off is a big plus.

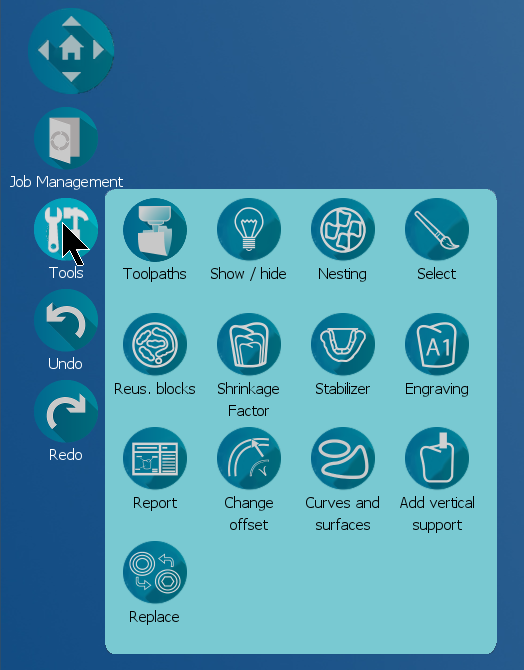

Secondary tools are tucked away into organized categories that are easy to access when needed. This keeps the workspace un-cluttered during nesting.

Undo / Redo

We all make mistakes from time to time – Being able to step back at the click of a button is a valuable tool.

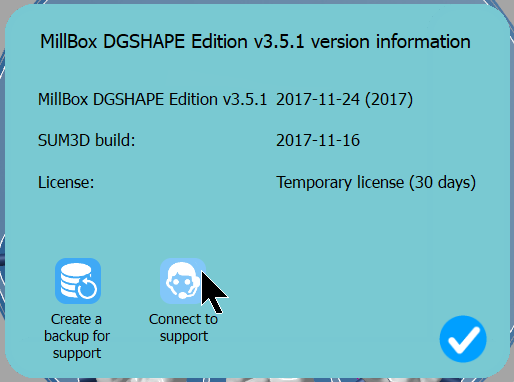

Support Tools

New Support Tools are available to dealers and users. Technicians can easily grant access to their machines for remote access and backup files can be easily created when needed.

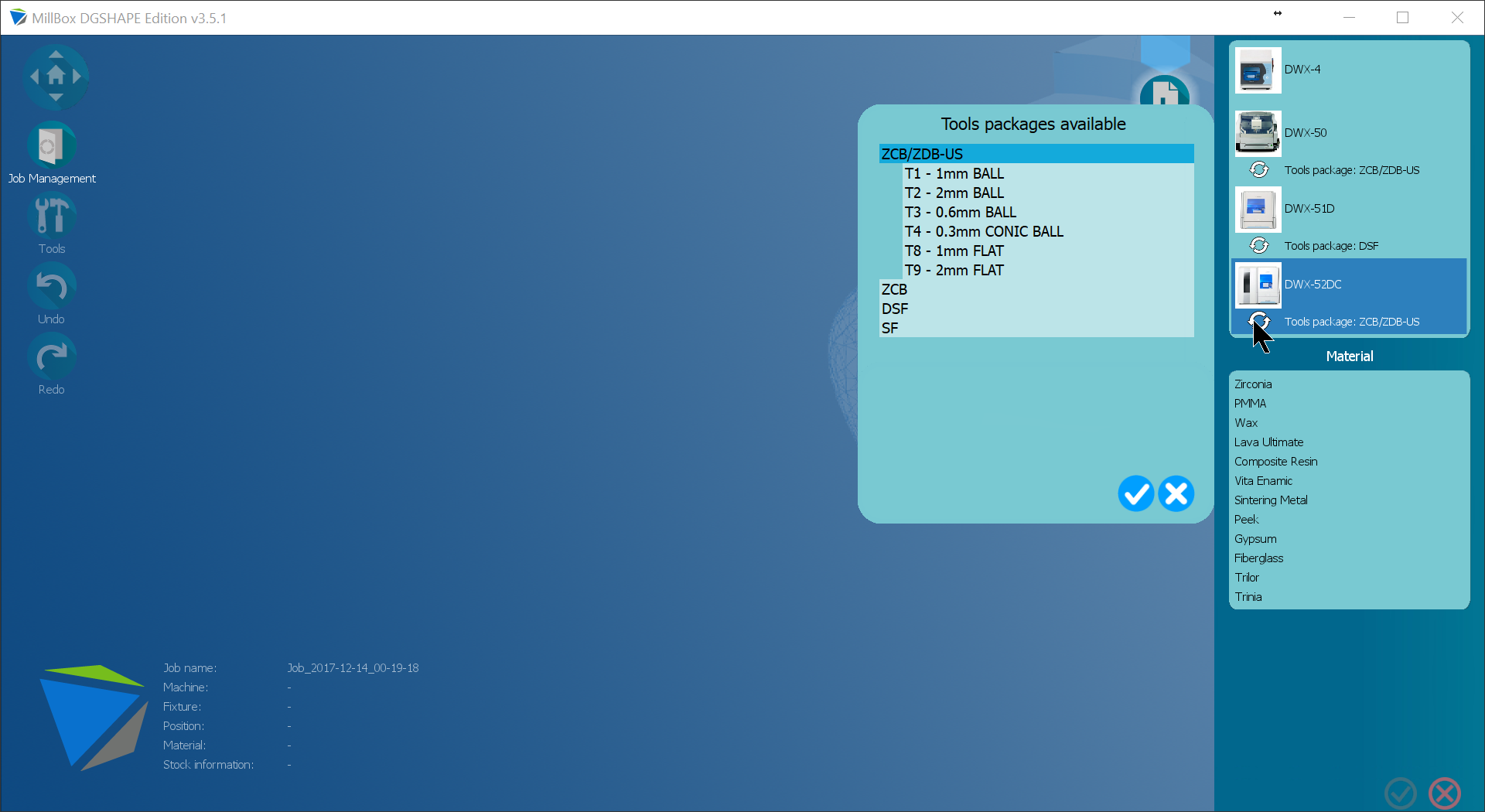

Tool Profiles

Users can now change pre-set Tool Profiles at the click of a button (As configured by dealer). This allows us to simplify the interface by only having one machine selection and easing the use of different length/sets of tool configurations. Users can always have access to the proper tools needed to get a job done. The tool slot assignments are easily visible and can be used by the user as a reference when needed.

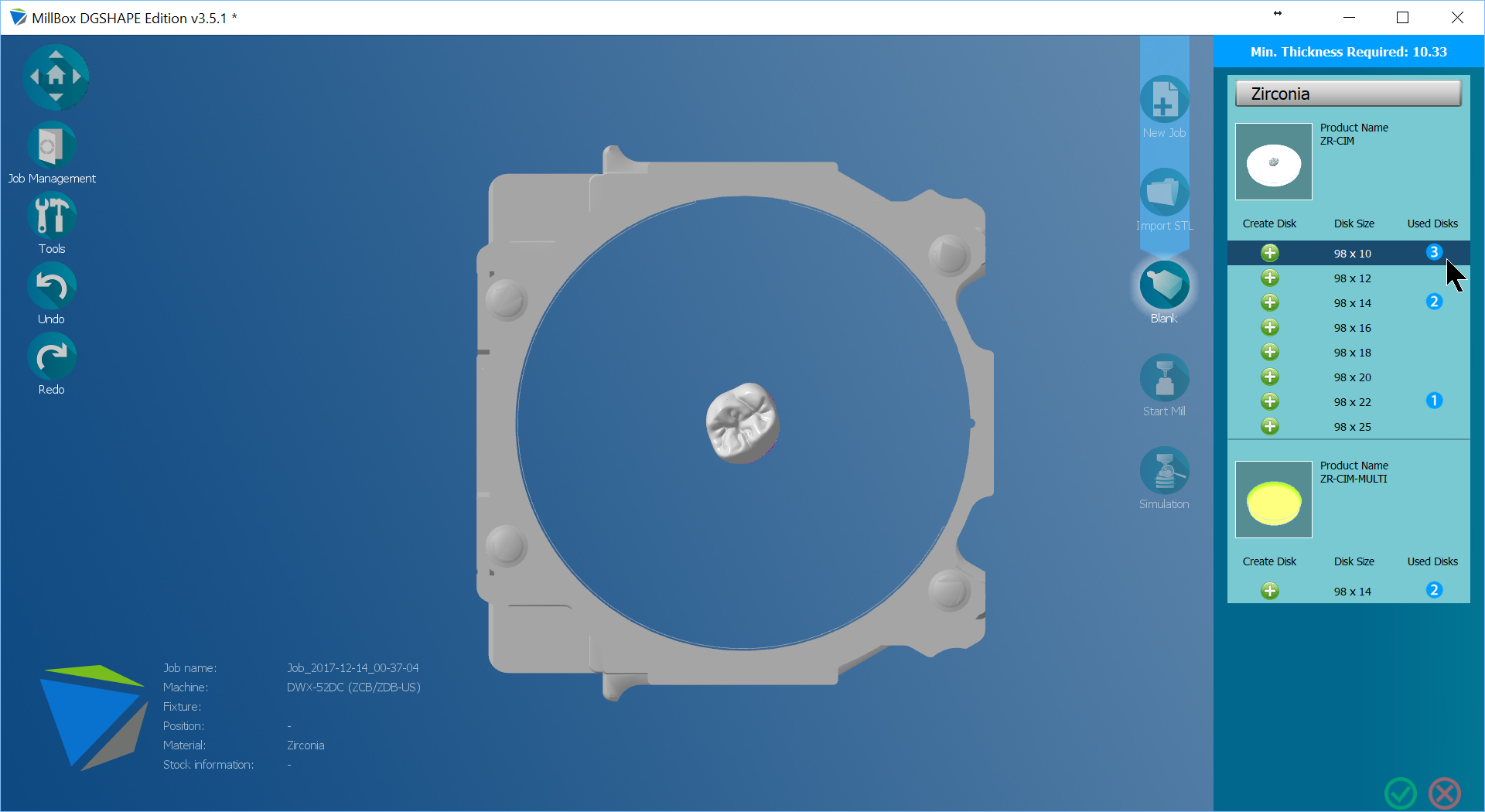

Sorting and Previewing of New and Used Material Files

MillBox sorts and displays available and partially used stock according to their sizes. This can help reduce the time taken in finding partially used materials for future milling jobs. New materials can be created at a single click of a button and available partially used materials are displayed to the right of the material list indicating how many partially used stock are available.

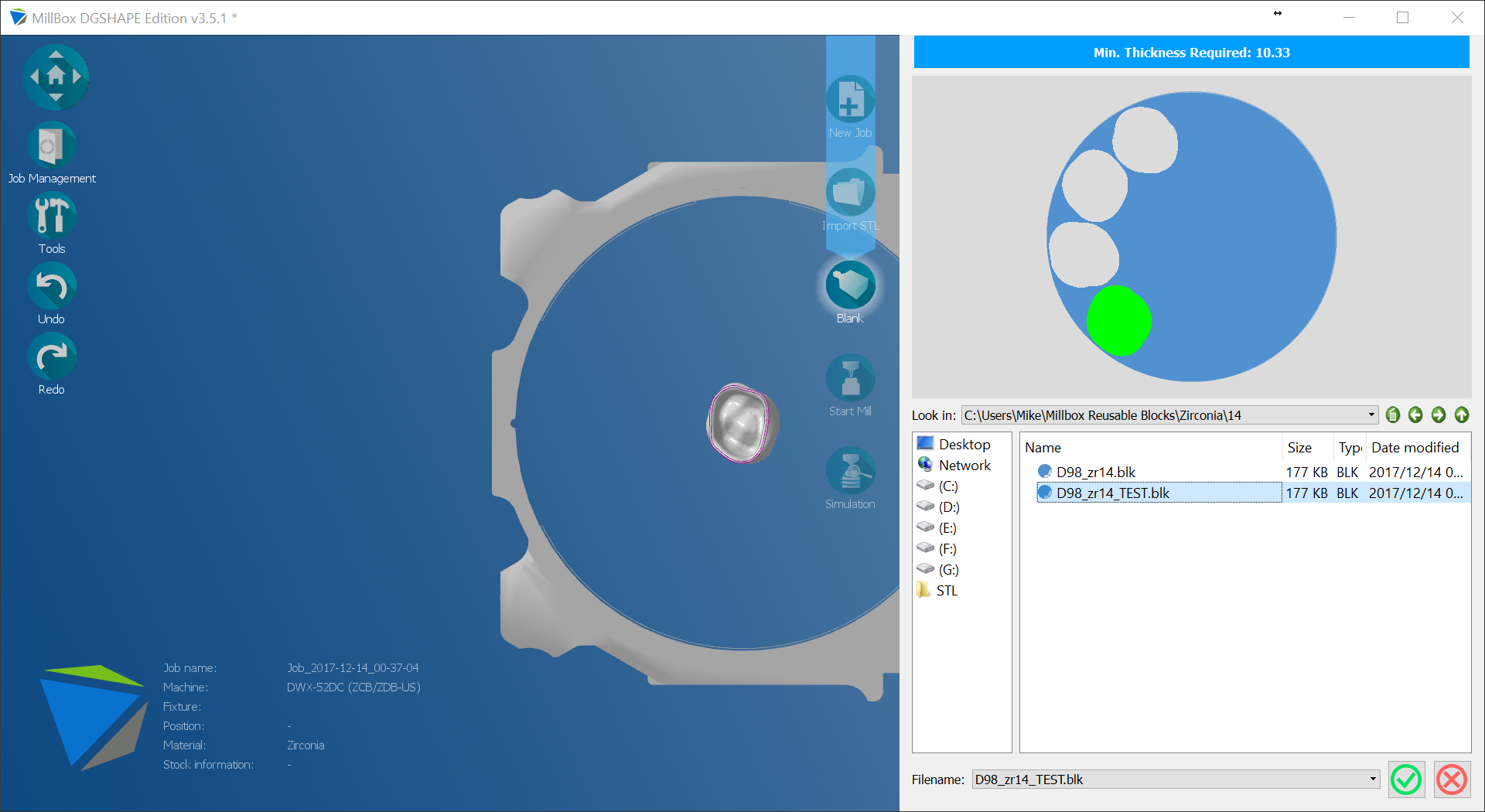

Users can get a real-time preview at how their imported parts will auto-nest inside of the partially used material. If there is insufficient space, the user is notified directly on the preview image.

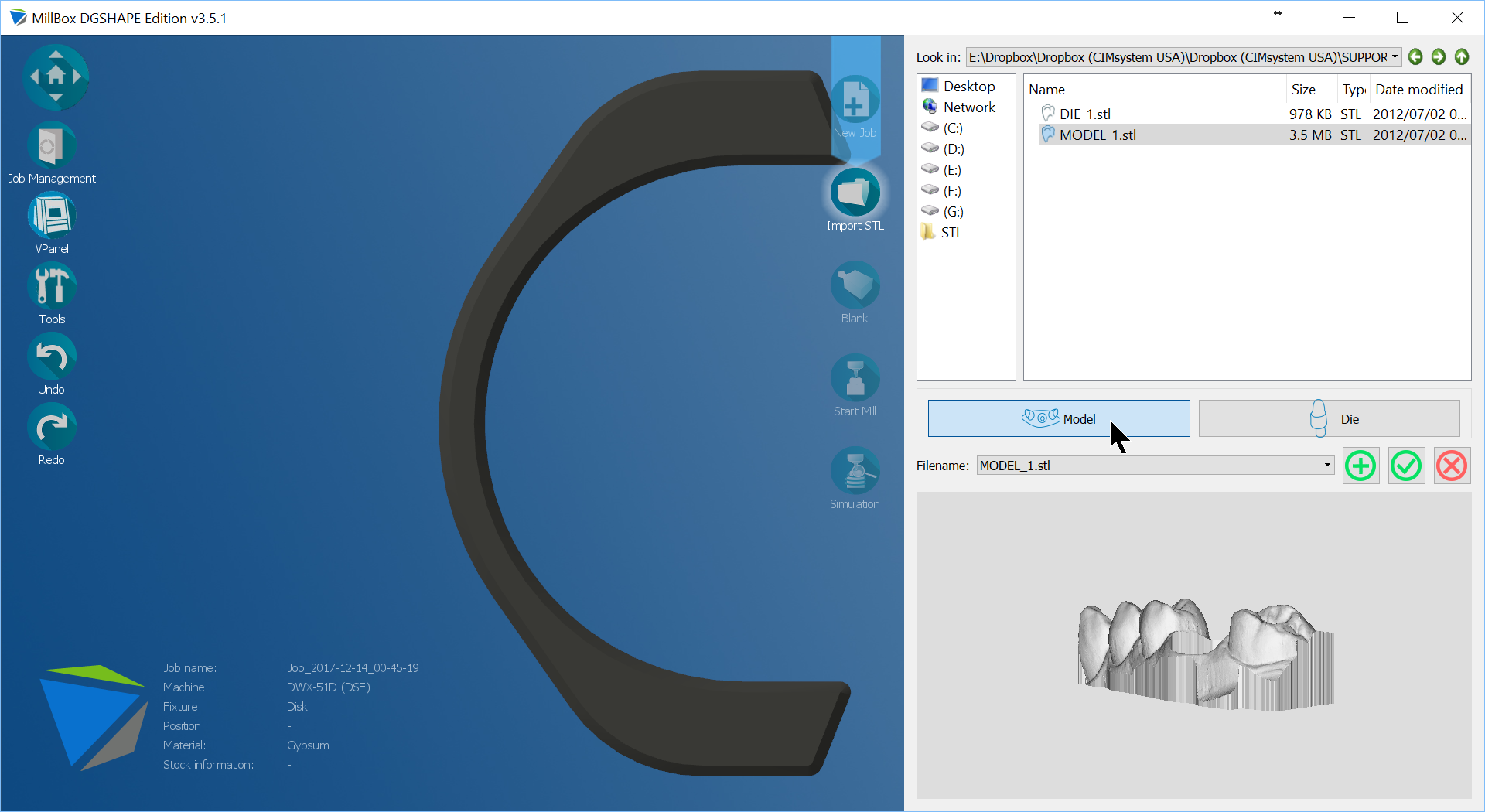

Smart Materials and Smart Object Types

When selecting a material to mill, only materials that are applicable to your machine are displayed.

Object / Restoration Types available as choices will now also be dependent upon your material selection. This ensures that the user is selecting the correct object / restoration applicable to the material.

As an example: If a user were to select Gypsum as a material, they will only see DIE and MODEL object types.

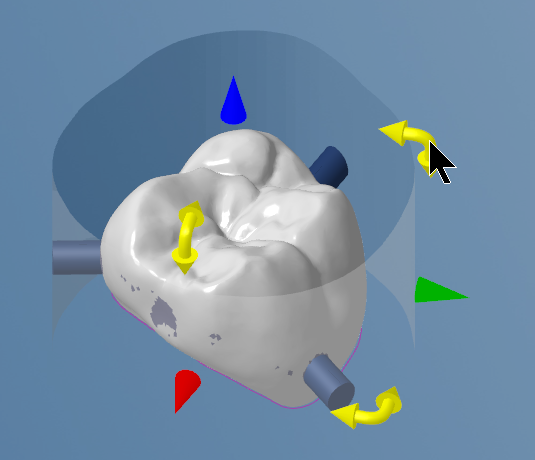

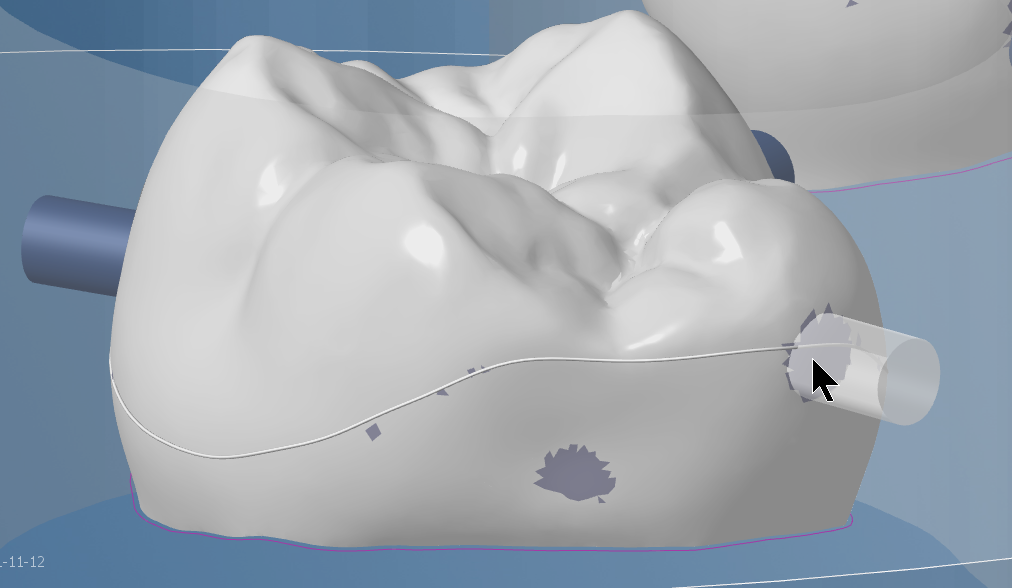

Support Pin Enhancement

Moving parts for optimal nesting and adjusting support pin placement have never been easier. Rotation controls are present on all parts.

Moving support pins are as simple as clicking and dragging them to the desired location. When moving support pins, the equator curve is displayed. Similar to indicating the height of contour, this shows us where the optimal placement of the support pins should be in order to avoid creating undercuts. This means a reduction in the time spent finishing the areas where support pins were placed in the post-production stage.

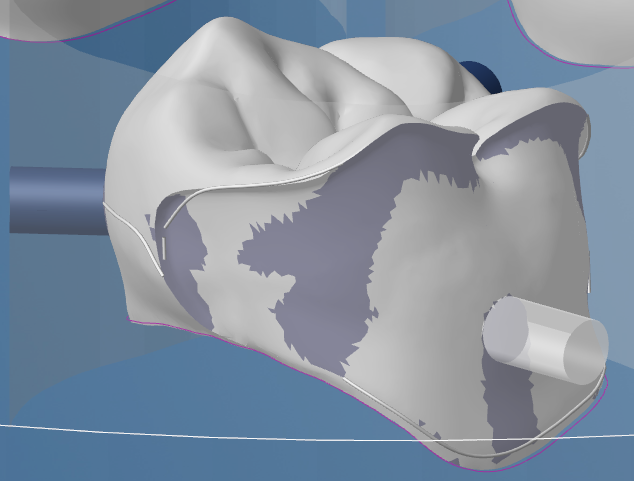

Undercut Visualization

Undercuts (due to design or support pin placement) are visible to the users directly on the part. This helps the user decide when and where to use complex toolpaths to mill these undercut areas.

Coming Soon

Queued Importing of STL Files

Available in 2018, MillBox users will be able to queue up the Import of STL Files. This means that while the CAM is working on processing each file during import, the interface is unlocked, which allows users to queue up subsequent objects / restorations for milling. Allowing importing files to process in the background will save valuable time during the nesting process.

These are really just a few compared to the many more ways MillBox has enhanced the Open Dental CAM experience. As a user of SUM3D myself, MillBox has really changed the game by taking SUM3D’s greatest strengths and building a very well-rounded CAM suite. MillBox is available as a stand-alone or out-of-the-box solution for any open mill and also as an upgrade for pre-existing SUM3D users.

If you are currently a SUM3D user, you can contact your dealer to inquire about upgrading to the new MillBox Interface. Fox existing users, It’s worth noting that there is a pre-requisite of running current software maintenance to be eligible to purchase the upgrade.